With the continuous improvement of environmental standards in the country, in recent years in the process of sewage treatment, odor odor control has been in full swing. Our company in Shanghai Municipal Engineering Design Institute (Group) Co., Ltd. under the guidance of the research and development of production: high strength and no support, no frame glass steel odor collection cover, has been in many sewage treatment plant upgrade project mentioned standard, and was widely praised and affirmed.

The glass cover (Overview)

The relevant technical parameters, FRP cover material:

Serial number | project | Experimental method | Test result |

1 | tensile strength MPa | GB/T1447 | 194 |

2 | tensile strength MPa | GB/T1447 | 13027 |

3 | elongation at break% | GB/T1447 | 2.4 |

4 | bending strengthMPa | GB/T1449 | 251 |

5 | Bending elastic modulusMPa | GB/T1449 | 12370 |

6 | Corrosion resisting bending strength retention | 5% hydrochloric acid solution immersion24h | 92.5 |

7 | 10% sodium hydroxide solution immersion24h | 91.2 | |

8 | impact toughnessKJ/m2 | GB/T1451 | 137 |

9 | PAP hardness | GB/T3854 | 42 |

10 | Hot deformation temperature | GB/T1634 | >200 |

11 | Air tightness | In vacuum diversion, vacuum pressure meter display | There is no obvious change in pressure gauge |

12 | Arch height around mm (vacuum pumping process) |

| 20 |

13 | Arch height around mm (hand paste process) | 25 |

Description: the above plane projection area is long 13700X wide 2000mm, area 27.7m2

Two, long service life:

Selection of high-quality materials and the most scientific formula: all all the alkali free glass fiber, the outer cover made by anti aging middle uv gel coat resin using high strength resin 196, inside epoxy vinyl ester anticorrosive resin, production process using vacuum diversion technology, greatly improving the strength and resistance of FRP cover corrosion and aging resistance, service life can reach 15 ~ 20 years.

Three, the diversity of shape design:

This is the advantages and characteristics of glass steel cover. According to customer requirements and the actual situation, according to the shape of the pond (circular, rectangular and irregular shape), a cover at the design and production of various shapes.

Four, excellent shape design:

I chose the most scientific design (has been a design patent issued by national patent bureau certification) (see the attached copy of the certificate), greatly improving the vertical span of cover (now the single span has more than 20m),

Five, easy installation, high load value:

The maximum longitudinal arch cover height is less than 1200mm. FRP cover shape are curved, and smooth surface, and a large area in the cover when using set combination plate reduce Mega wind pressure, greatly improving the ability of resisting typhoon.

I produced the glass steel cover during the installation process, allowing the construction personnel in construction and running top cover. When the installation is complete, you can allow the uniform live load limit is 0.5KPa, and in the long run under load, the maximum deflection of the cover is not greater than L/200 (L is the cover span).

Six, convenient and quick installation:

1, glass steel cover before production in accordance with the design requirements, in accordance with the actual situation, accurate mapping, calculation to produce glass steel cover. The product to the scene and can be placed directly sequentially, placed side edges fixed in place, to speed up the progress of the installation.

2, FRP cover according to the actual surveying and mapping production: uniform shape and uniform size, load distribution, both the pool shape how old or new, renovation project pool in a reasonable way to install the cover, without considering the structural reinforcement or establish a fulcrum, upgrading projects without stop construction.

3, after the installation of FRP cover: design science and materials of high strength, excellent production performance and special glass steel products, bring convenience to the users and installation. The cover can open manhole, according to the actual needs of the activities of air inlet and outlet, convenient installation and construction of pumping and air supply system.

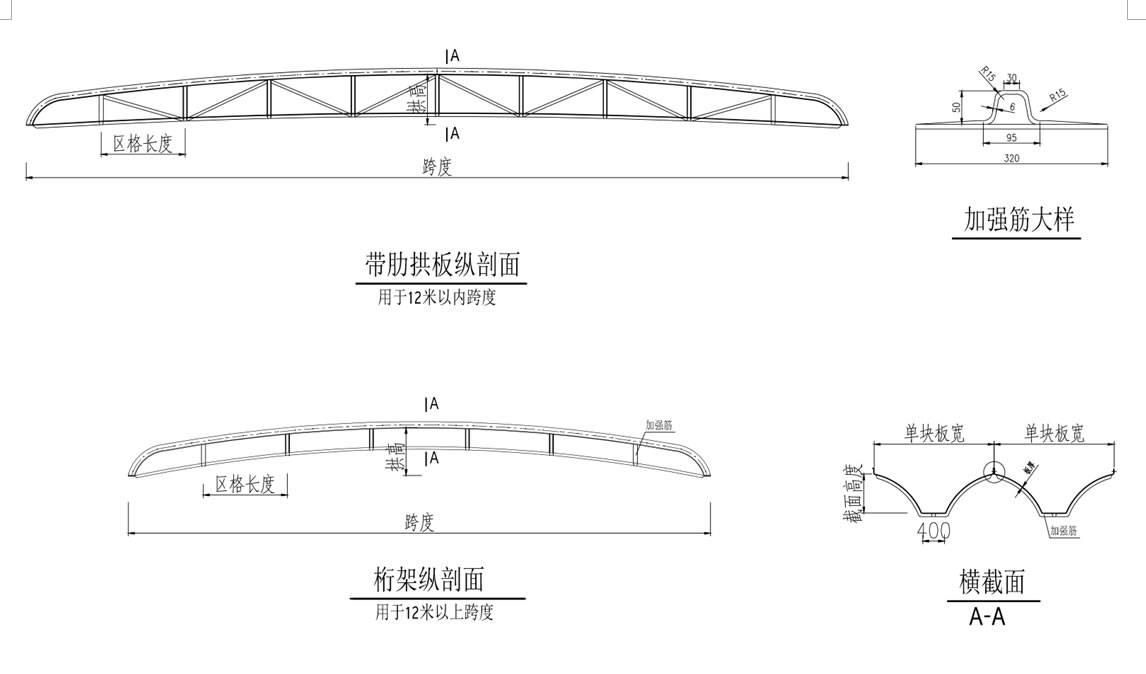

Design, material and geometrical parameter table of double arch glass fiber reinforced plastic gas gathering arch plate::

Design, material and geometrical parameter table of double arch glass fiber reinforced plastic gas gathering arch plate::

三、几何差数

Longitudinal section(m) | cross section(mm) | ||||||||

span | type | High arch | Partition lattice | Single plate width | span | Maximum section height | Plate thickness | Flange plate, support end plate thickness | Reinforcing bar |

10 | High arch | 0.8 | 7 | 1500 | Half | 400 | 5 | 10 | 50x95x5 |

13 | truss | 0.85 | 10 | 1500 | Half | 650 | 6 | 10 | 50x95x6 |

15 | truss | 1 | 10 | 1500 | Half | 750 | 7 | 10 | 50x95x6 |

18 | truss | 1.2 | 12 | 1500 | Half | 900 | 7 | 12 | 50x95x7 |

20 | truss | 1.35 | 14 | 1500 | Half | 1000 | 7 | 12 | 50x95x7 |